By Tracey BAKER – EAZY STOCK

Broken down to the bare essentials, inventory management means having the right stock (i.e. the things your customers want to buy) in the right place at the right time. It means having items on shelf when customers come looking for them, otherwise you lose a sale and customers will go elsewhere. Disappoint too many people, and your brand reputation will start to take a dive.

But as well as having enough stock to meet demand, good inventory management also means not over-stocking. Having more products than you can actually sell just means that you have capital tied up that you can’t release. Long term, you either have to take a hit on your profitability by selling the excess off at a discount, or write it off altogether.

For retailers, then, inventory management is a delicate balancing act, but one that is very important to get right. It is a process that can broadly be split into two parts. On the one hand, there are the practical aspects of placing orders and moving and storing stock that we widely associate with logistics and stock control.

But on the other, there is the need to understand the supply and demand factors that influence how much stock you need and where and when you need it. This includes forecasting demand, so you can predict how things like seasonality, promotions and new product launches are likely to influence future sales patterns. It also includes keeping an eye on your supply, so you know you can get the right stock to replenish what your customers want.

The need to combine the two strands makes inventory management a highly dynamic and complex task. Because demand and supply patterns for products are fluid and change according to season, price, shifts in consumer trends and demographics, hitting that ‘just right’ spot between under- and over-stocking for any given item at any given time is far from easy.

Managing inventory from point of sale

The good news for retailers is that technology has an answer. Whereas inventory management once involved the daunting task of going through endless spreadsheets trying to tease out the patterns in demand, and then juggling separate manual processes for stock-taking, placing orders, making payments and managing logistics, now that there is software that can automate the whole process. And that means that your efforts to optimise inventory can begin at point of sale, the moment a purchase is completed.

For example, EazyStock is a cloud-based inventory optimisation platform that can be integrated with standard ERP systems to help small and medium-sized businesses improve their inventory management capabilities. The benefits to retailers of running a solution like EazyStock include:

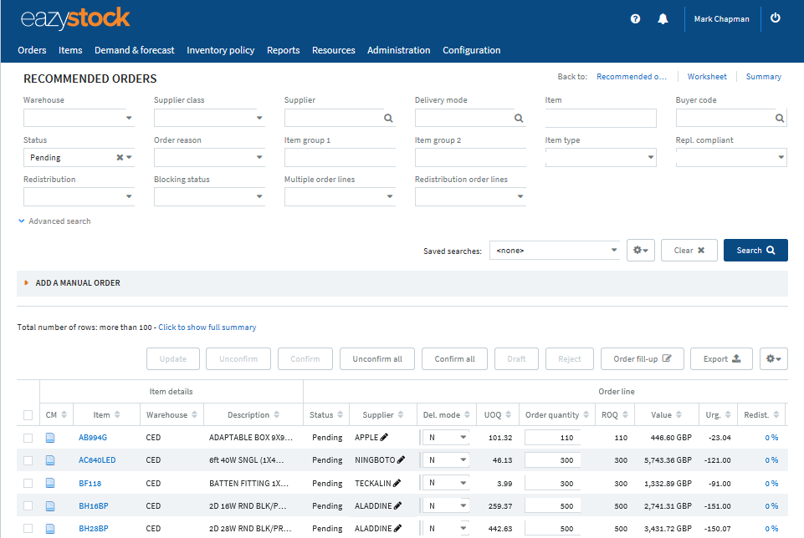

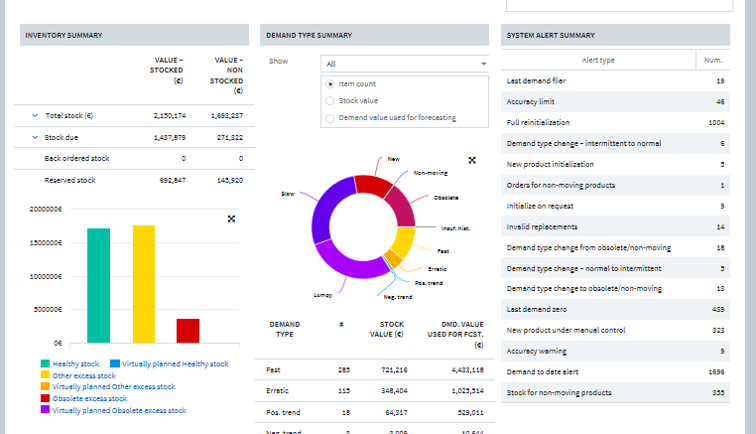

- Precision demand forecasting: EPOS terminals allow retailers to create a data point for every sale they make, logging what was bought, where, when, what was paid for it, and possibly information about the customer who bought it, too. EazyStock utilises the historical demand data and turns it into future predictions, giving retailers access to in-depth intelligence on which to base their stock replenishment decisions. Items which are affected by seasonality and fashion trends are identified and future forecasts are automatically updated to ensure they’re as accurate as possible.

- FIne-tuned replenishment: Getting your stock levels ‘just right’ requires more than just good demand forecasting. It also needs some additional fine tuning. This includes taking account of supplier lead times, so you know when you need to order by to ensure you don’t run out before the delivery arrives. For example you may need to bring forward order dates at the busiest periods because suppliers will be facing higher demand, too. Inventory optimisation software, like EazyStock takes account of supplier lead times when calculating reorder points, to prevent stockouts. It will also work out an adequate level of safety stock to provide some buffer against unforeseen variations in demand without landing the business with an excess of stock that will eventually eat into profits.

- Stock level optimisation: Not all products are the same – they sell at different rates, and have different margins (because they sell at different price points and carry different wholesale costs). A common mistake made by retailers is to over-stock high margin products which usually sell in relatively low volumes. This ends up blocking space in your storeroom or warehouse, making it difficult to find room to replenish products that fly off the shelves faster – and increasing the risk of these going out of stock. EazyStock is able to analyse demand patterns to identify the high-volume products that sell quickly and which you should always keep in stock, and those that, despite usually offering better margins, you can perhaps afford to replenish less frequently or even sell to order.